Guides

6 Top Tips For Looking After Your Sewing Machine

Looking After Your Sewing Machine

Looking after your sewing machine is a great idea and not hard to do. Following a few simple principles in using the right tools and basic maintenance will should keep your sewing machine in tip top condition for many years.

Mr More Sewing has serviced over a thousand sewing machines (although a number of these are the same machines he has seen more than once!) and wants to share his top tips for looking after your sewing machine. What you can do to look after your sewing machine and stop minor issues from becoming major problems!

1. Use The Right Sewing Machine Needle

How often do you change your needle? You should be looking to change it every 8 hours or sewing or at the start of a new sewing project. Pick the right needle type for your fabric and thread (stretch needles for knitted fabrics etc.). Make sure your needle is pushed up in the needle bar as high as it can go (it should hit the stopper). A blunt needle or a needle set at the wrong height will affect your sewing.

The needle plate is the metal plate that the needle passes through as you sew. Look the the hole the needle passes through. Is there damage to the plate or around the hole where your needle has hit it? This can damage the thread or make it snap and you will need to get it repaired. It is also a sign that you are either pulling the fabric through the machine and making the needle move or the needle is being moved by hitting something (a pin?) or is too light for the material you are working on (and is bending as it hits the fabric). Try a fresh, heavier needle and see what happens.

Use good quality needles – cheap needles are a false economy. Schmetz, Organ, Inspira and Prym are all good makes and the ones we tend to stick to.

2. Use A Good Sewing Thread

Use good quality thread – we like Gutermann and Coats Moon thread. Both are great quality consistent thread. Cheap thread can be too weak and have too much lint in them which means the thread can break when sewing or get caught in the sewing machine. Neither is a good idea!

For normal sewing, use the same thread on the top and bottom bobbin of your machine, mixing threads (particularly new and old) can cause tension and stitching problems. OF course this can be different if you are using a non-standard thread (shirring elastic etc.). If in doubt have a read up on the internet before you start to sew.

Always thread your machine with the presser foot up. This means the tension discs are open when you are threading the machine and the discs will close round the thread when you drop the presser foot to sew. Threading with the foot down means the tension discs are closed and it is possible that the thread will sit on top of the tension discs – meaning your thread is not tensioned and can slip into your machine (particularly the take up lever which can make your machine seize up).

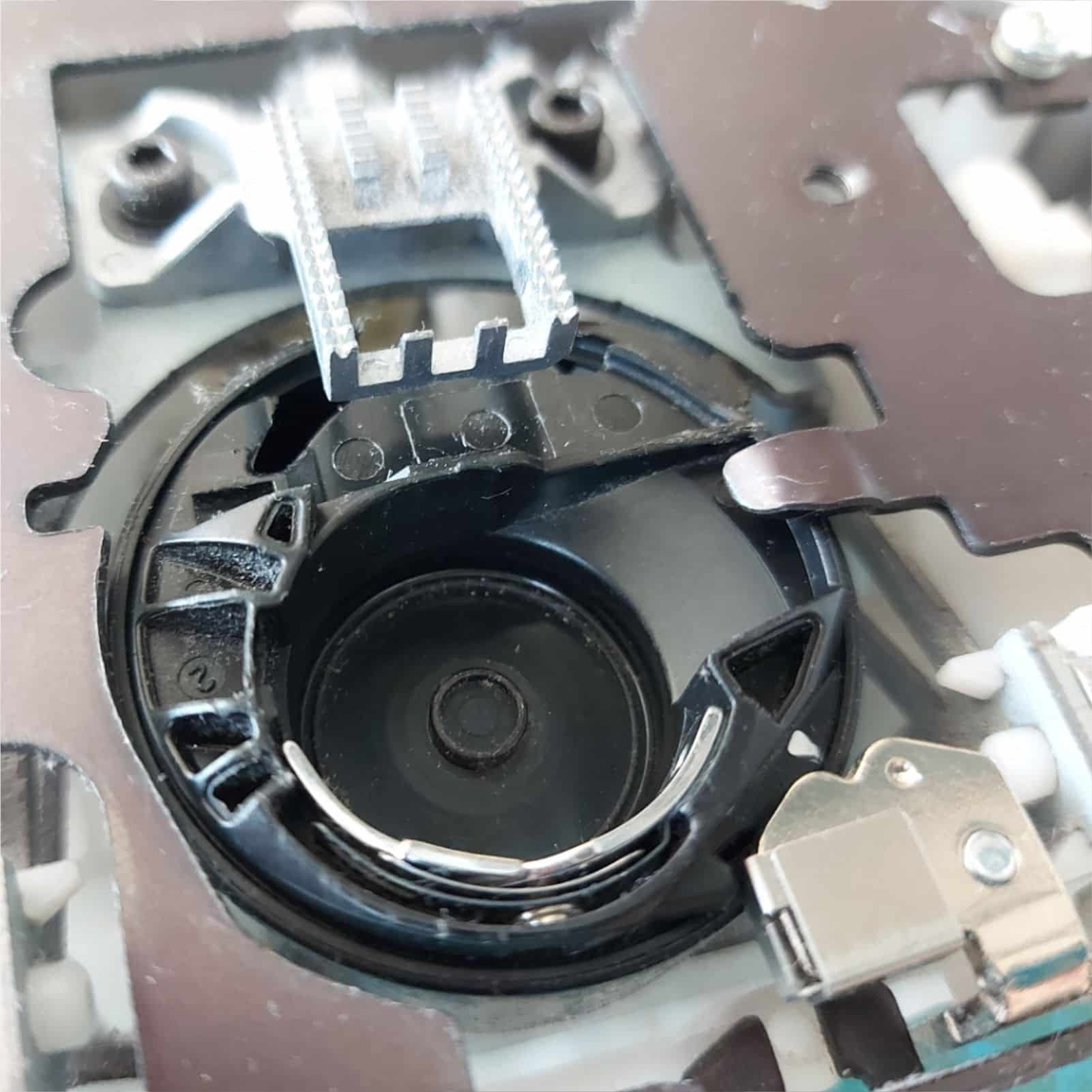

2. Using The Right Bobbin

Use the right bobbin for your machine – the wrong bobbin can cause tension issues or potentially damage your bobbin case. Check your user manual to make sure you are using the right bobbin.

Scratched, bent or broken bobbin? Throw it away!

Oiling Your Machine

To oil or not to oil – that is the question! The answer is (almost) all cases is yes!

Only use sewing machine oil – don’t use 3-in-1, it’s too heavy. Don’t use sewing machine oil if it is old and coloured up. Treat yourself to some new oil.

Don’t pour the oil straight in – that is far too much and may end up on the thread or fabric. The bottle you have should last for years. Put a little oil on a cotton bud and touch it to the machine where the oil is needed – that is enough.

Only put oil on metal parts. Have a new machine that the book says does not need oiling? This is because just about all of the moving parts are plastic. Even then, if the machine starts to run tight or squeals – it may need just a touch of oil.

4. Cleaning Your Machine

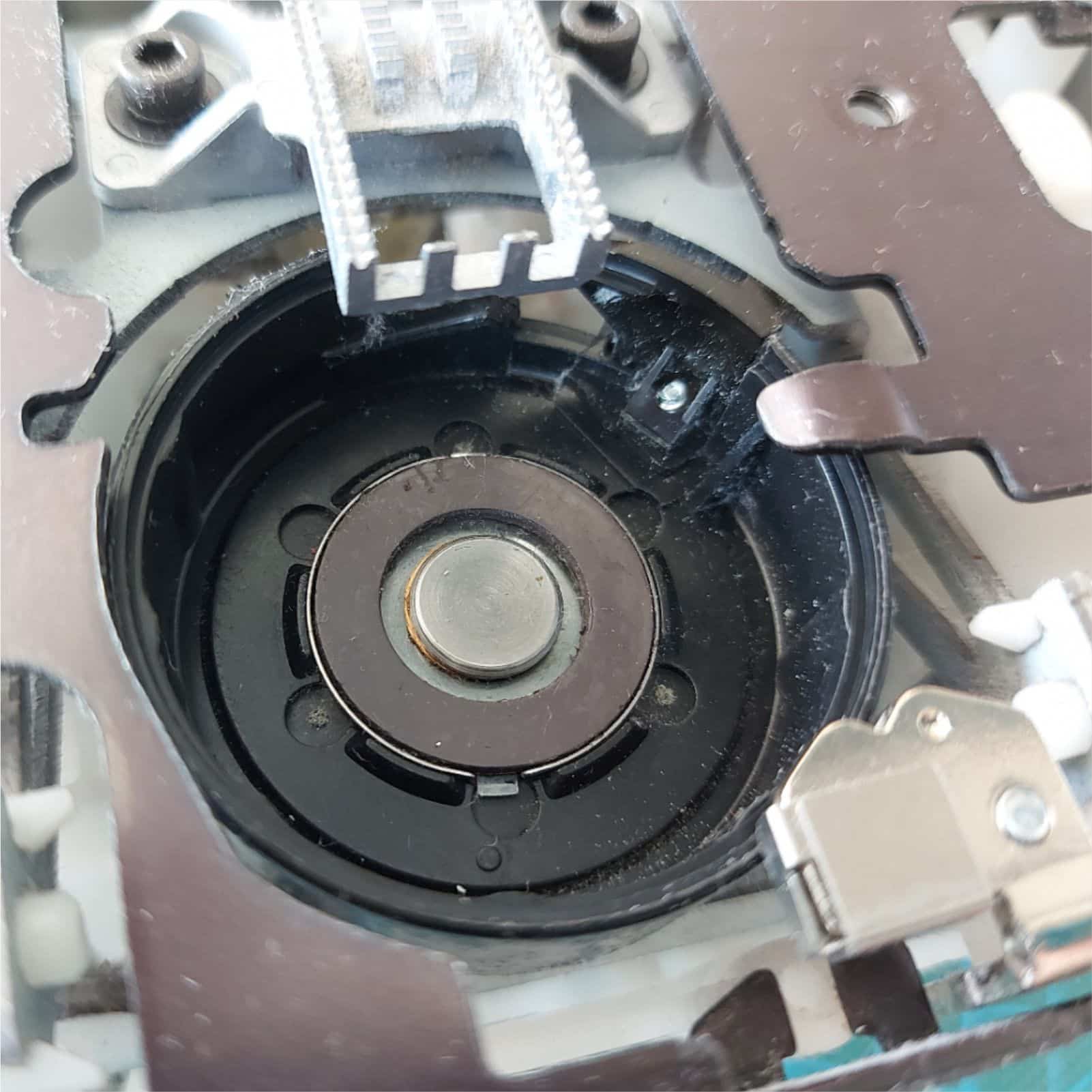

The main place where fluff can collect is under the needle plate and around the bobbin. The best way to clean this area is with a small paintbrush (like you would use for watercolour painting).

One very important point – don’t blow (or suck) the fluff. Blowing it will just push the fluff deeper into the machine where it is harder to get rid of. Sucking (using a vacuum cleaner) will get rid of the fluff but the last thing you want to hear is something hard rattling up the pipe! All those screws are there for a reason!

To clean under the needle plate, unscrew and remove the needle plate. Take out the bobbin case. Use the paintbrush to flick any fluff you see out of the machine. Check the bobbin case as well and clean it if needed.

If you have a top loading machine the bobbin case only fits back in one way with the case resting up against a little spring on the lower right hand side.

Put the plate back on and screw it back in.

5. The Bobbin Winder

If you have an older or basic machine it can be possible to sew with your machine with the bobbin winder engaged. Don’t! Always check before you start to sew. If you sew with the bobbin winder engaged for any length of time, the bobbin ring (which is made of rubber) can start to develop a bald spot (which means it will need to be replaced) or worse still will melt inside the machine! Cleaning melted rubber out of the workings of a sewing machine is not fun and can cause a problem with motor.

If you follow these simple hints for looking after your sewing machine – it should run better for much longer!

Happy Sewing!