Guides

What Happens in a Sewing Machine Service?

Getting a Sewing Machine Service

When you take your sewing machine in for service, have you ever wondered what actually happens? Hopefully, if it is done properly, a sewing machine service should mean you notice a positive difference when you get your sewing machine back. The core elements of a service mean checking and fixing a number of issues.

Cleaning the Sewing Machine

Not just a cosmetic clean to make the machine look its best but also cleaning out fluff, snapped thread, and congealed and excessive oil. This means opening the machine up, taking off most, if not all of the outer case and making sure the working parts of the machine are clean and oiled (if necessary). Compacted fluff and fibres can mean that the feed dogs and bobbin are not working effectively. Trapped threads can make the machine run ‘tight’ (or seize up completely in the worst cases). Lack of oil can also make the machine seize up, over oiling (or the wrong type of oil) can mean that oil gets onto the thread or fabric you are sewing with and can also start to degrade plastic parts of the machine over time.

Tension Check

Both the top and bottom threads need to be held under tension. The two tensions also need to be in balance. Most people know that the top thread tension can be adjusted with the tension wheel. What most people don’t know is there is also a tension setting on the bottom bobbin case.

Timing

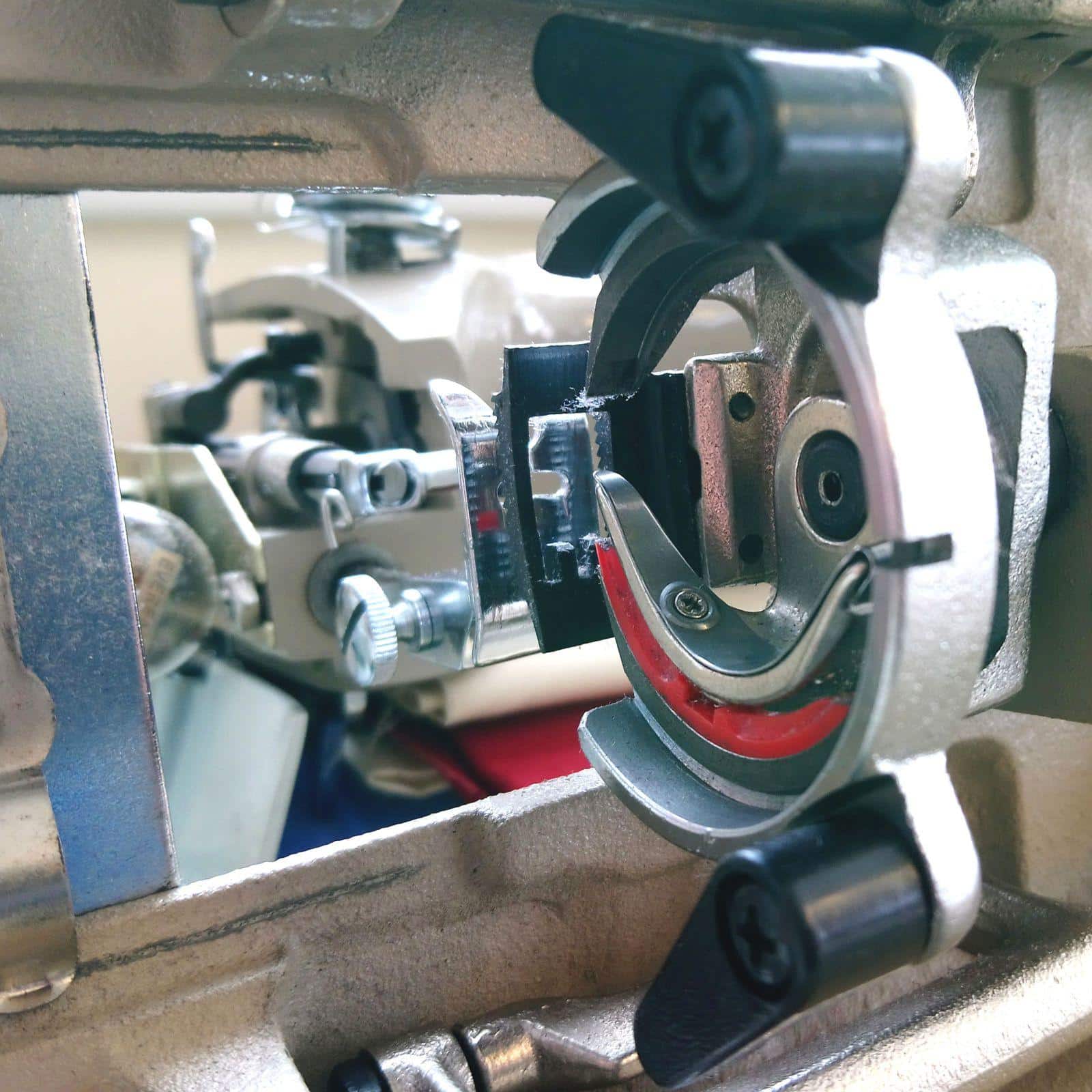

A sewing machine is, at its core, designed to bring the sewing machine needle and the shuttle hook (this runs behind, or above the bobbin, depending on your machine) together at the same time and place. Any variance in this and there is every chance that the machine will either produce skipped stitches or not sew at all. Why does the timing change? The most likely reason is that the machine has been jarred in some way (for example, bending or breaking a needle, catching a pin with the needle (a big no-no, never sew over pins – it is just not worth the risk) and the vibration causes the gears, bed shaft or needle bar to move and suddenly the machine is out of time.

Checking The Functions

This will include stitching off on a straight stitch and widest zig zag stitch. Why a zig zag stitch? Well that gives the best indication of tension and timing the two essential elements that have to be correctly set for your machine to produce the best stitch possible. Skipped stitches or a zig zag stitch that looks as if it has been pulled tight on the underside give an indication that something is wrong with the timing or tension (or both!). The effectiveness of the bobbin winder, feed dogs and foot pressure should also be checked. Other elements of a machine that would be checked include inspecting the bobbin case. If it is damaged or not fitted properly, the machine may not sew at all. Is the correct bobbin is being used? The wrong, or damaged, bobbin can cause issues with sewing. If the machine comes with thread, is it effective? Old or cheap thread can cause issues if they are too weak (or too strong).

Other things to consider

How long does a sewing machine service take? Done properly and thoroughly, a full service can take a few hours, older machines tend to be easier to take apart, some modern machines are very complicated and it can take a long time just to take the case off!

You should always expect your machine to be returned to you with a fresh needle (a blunt needle can cause stitching issues) and a stitched example of straight and zig zag sewing to show you the machine is stitching effectively.

If you are local and want to know more about sewing machine servicing – check our page:Sewing Machine and Overlocker Repairs and Servicing

Enjoy More Sewing!